Surface technology

Metal impregnation systems

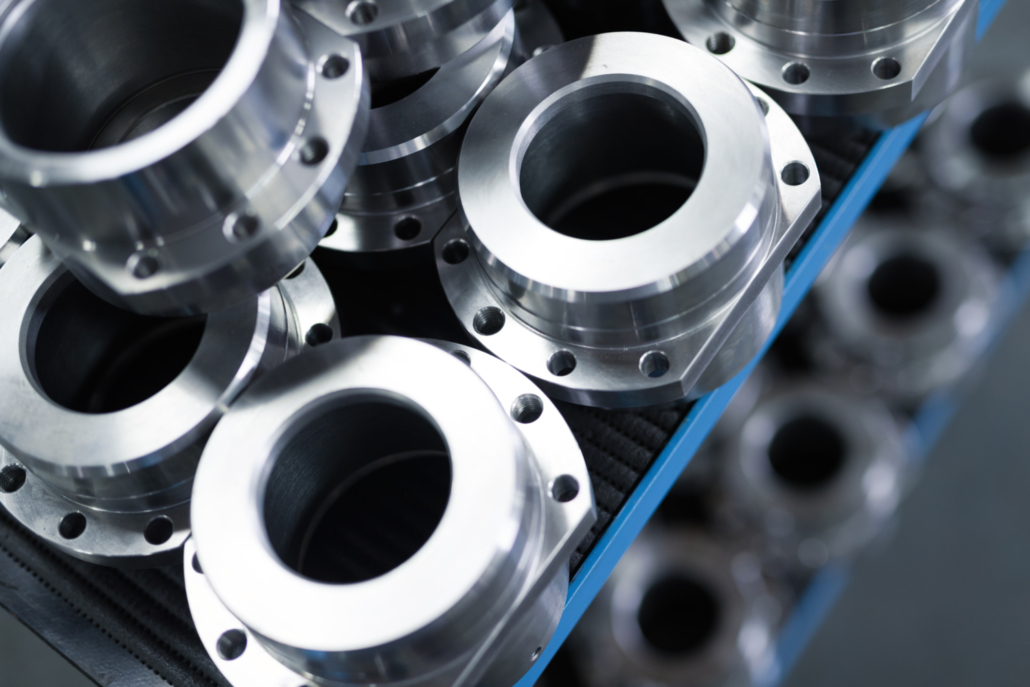

In mechanical engineering, metals and alloys are the most important of all materials used. This is because they are highly rigid and malleable while offering good electrical and thermal conductivity. In addition, metals can also be melted and cast.

Even though foundries use the most careful production techniques, it is often the case that products do not demonstrate leak points until after processing and can therefore no longer be used. In addition, cast parts that are initially impervious can become permeable during further processing by cutting into enclosed pores.

In all system types, the impregnation process is performed in a vacuum. The parts are first evacuated until dry so that any adherent residual moisture is removed along with air from the pores. The workpiece is then flooded with resin and the vessel is aerated after a rest period. This process ensures that the resin completely seals the pores.

Our impregnation systems are specially designed for these components and customer requirements. We offer a complete range, from simple, manual systems to fully automated systems with process visualisation.

Interested?

If you have any questions about our services or would like to receive an individual offer, feel free to contact us! Simply call us on +49-2871-21927-0 for a personal consultation. Or email us at info@meier-prozesstechnik.de.