Vacuum drying enables product-friendly and effective drying even at low temperatures.

The principle of Vacuum Drying

In order to achieve product-friendly and fast drying at low temperatures, even from deep pores, it is necessary to refer to the special field of drying technology – vacuum drying. The complete product is placed in the vacuum chamber. The pressure is now lowered until the saturated vapor tension is reached. From this point on, the water evaporates and is discharged through the vacuum system.

In most cases, the specific heat of the product to be evaporated is much lower than that of the base material. This material ensures that the temperature drops only slightly or not at all.

The pressure (the vacuum) reaches every spot so that the moisture evaporates completely. The result is homogeneous drying within a very short period of time. The necessary thermal energy is usually brought by the product from the upstream process. If the available energy is not sufficient, external energy is added in addition.

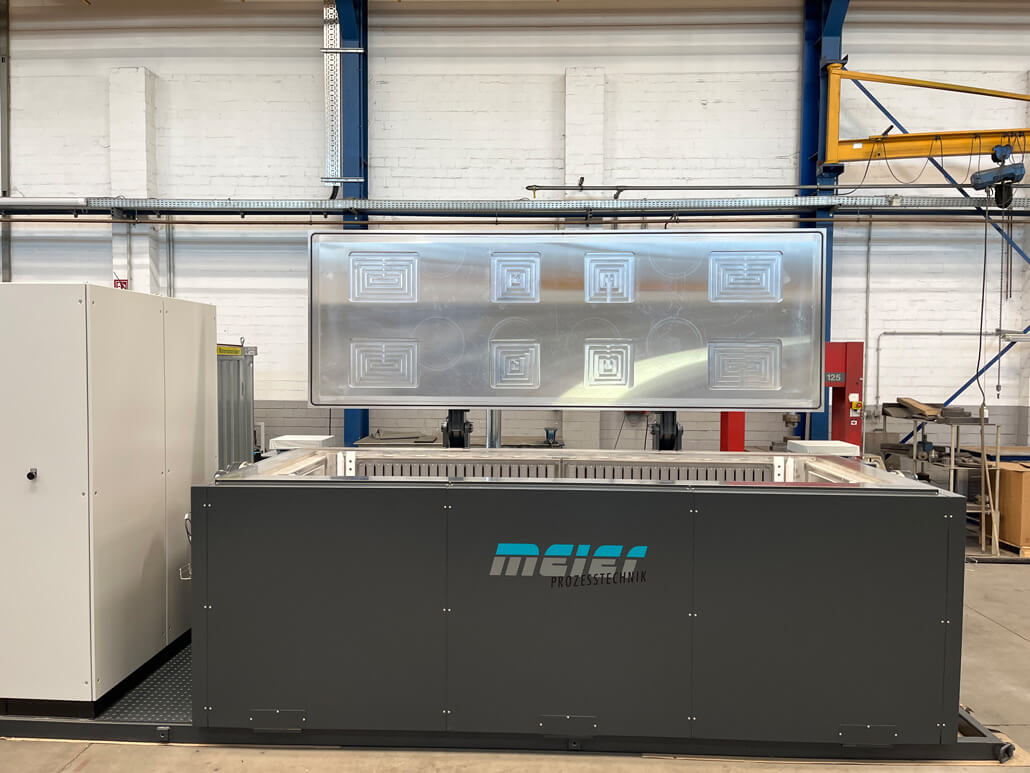

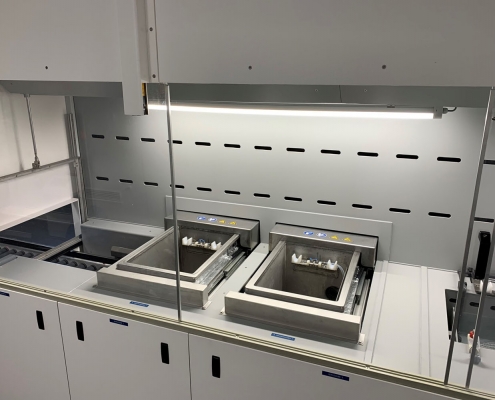

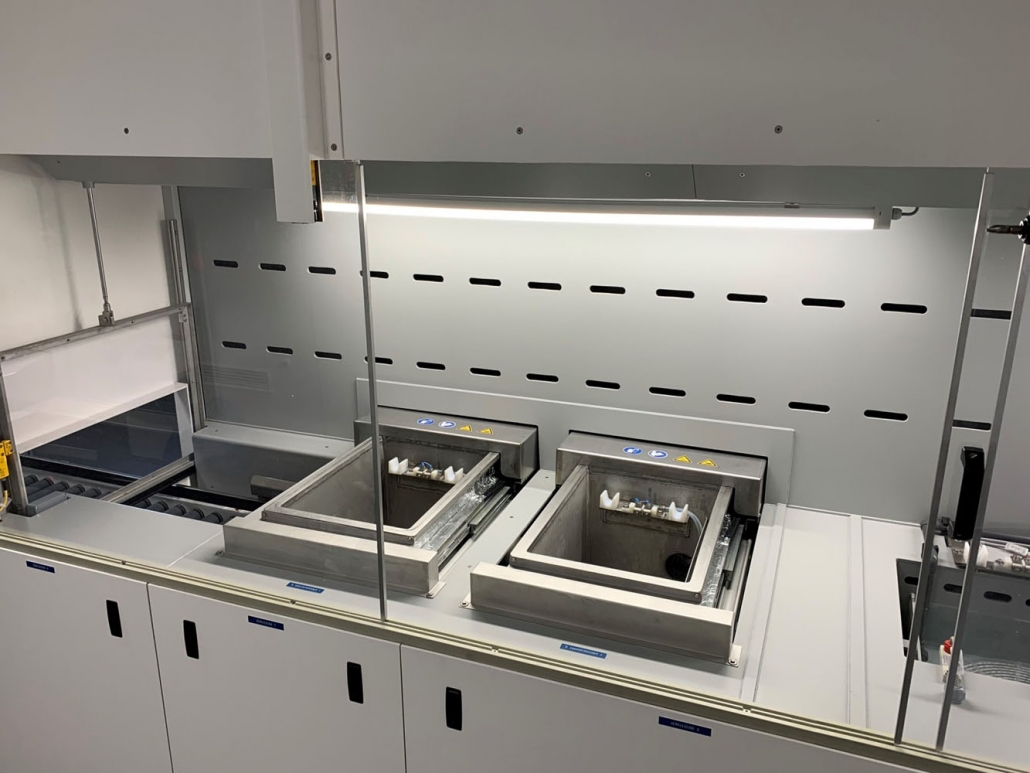

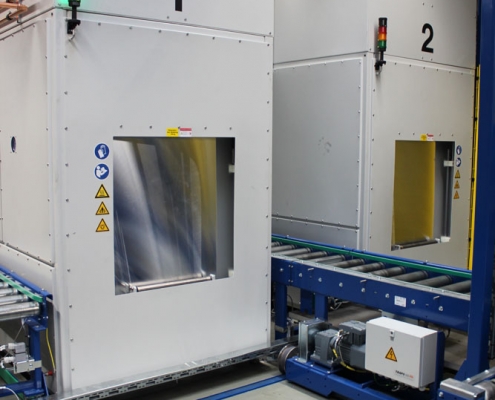

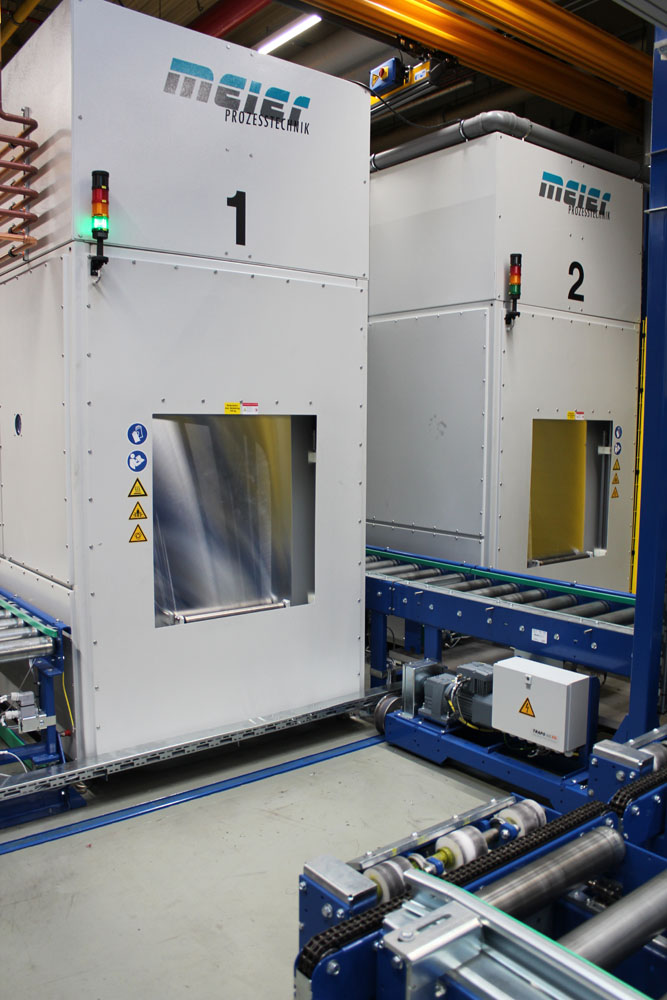

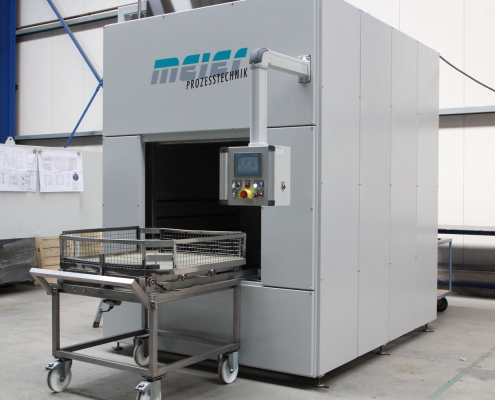

Vacuum Drying Systems

Due to the wide variety of drying requirements, our vacuum dryers are usually specially designed to meet your needs. Due to the large number of vacuum drying systems realized so far, we can fall back on standardized components and solutions.

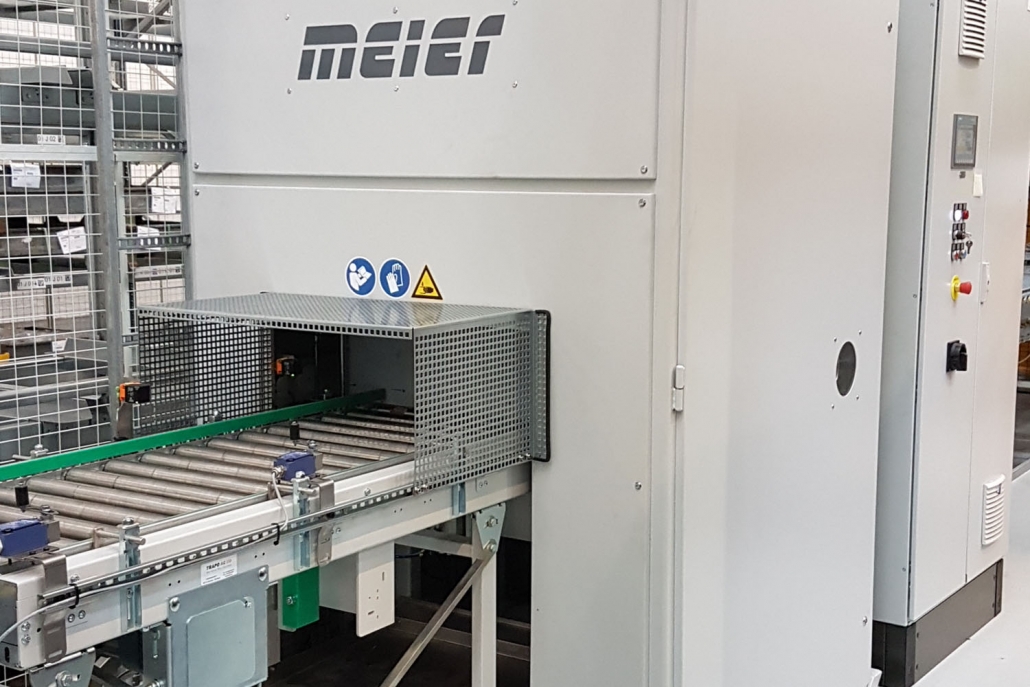

Our dryers can also be easily integrated into existing production lines at a later date, or operated as a “stand-alone solution” with their own PLC control. Request information now!

Possible designs and components of a Meier vacuum dryer:

We offer vacuum dryers in round, square, continuous, top-loading or special designs.

- Heating systems like infrared, heat exchanger or circulating air systems

- Central vacuum pumping stations

- Conveyor systems

- Visualization and logging

- Explosion protection (ATEX) with own expertise

- Vacuum-tight feedthroughs for the rotation of fabric racks

- Air ducts for uniform heat treatment

- Clean room technology

- Preparation for exhaust air ducting

- Plant evaluation, relocation, retrofit

Advantages of a Vacuum Dryer

Many products are particularly temperature-sensitive due to their special properties. Drying at high temperatures would impair the original properties of the product and is therefore unsuitable. Vacuum drying allows moisture and solvents to evaporate at low temperatures without affecting the product.

Vacuum drying offers some decisive advantages over other types of drying:

- Reduced energy/operating costs

- Short cycle/drying times

- Drying process that protects materials

- Drying independent of geometry

- Maximum level of drying and quality

- High purity

- Corrosion problems ruled out

- Low maintenance required

Application areas:

- Automotive and rail industry

- Electrical industry

- Research and development

- Glass and ceramics industry

- Aerospace

- Mechanical and systems engineering

- Medical technology

- Metal processing industry

- Surface industry

- Semiconductor industry

Vacuum Dryer for rent

You need a vacuum dryer for a limited time? Our rental equipment is available to you immediately. We are happy to provide you with a suitable rental offer.

Interested?

If you have any questions about our services or would like to receive an individual offer, feel free to contact us!

Simply call us on +49-2871-21927-0 for a personal consultation. Or email us at sales@meier-prozesstechnik.de