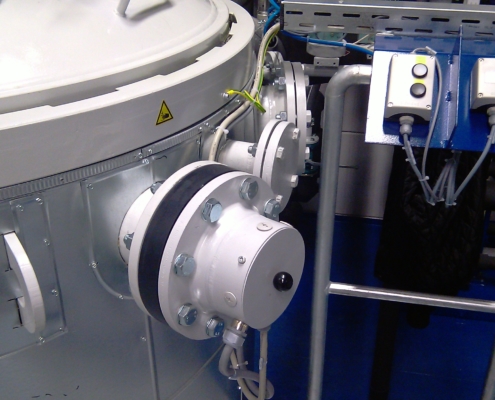

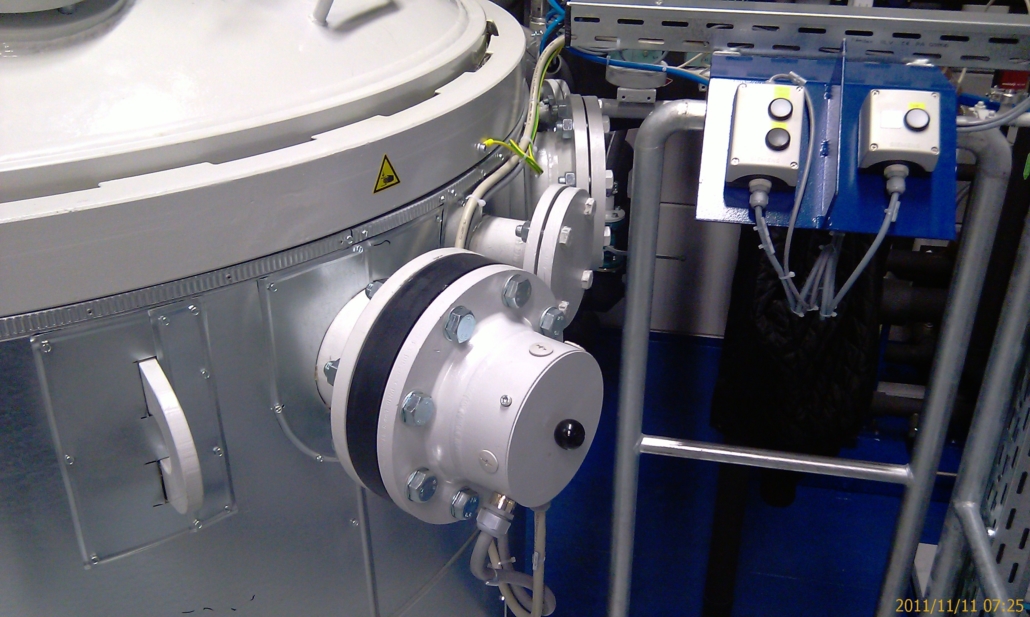

Our retrofit achievements

The key factor in this decision is cost-effectiveness. It is often the case that existing electrotechnical equipment, like automation and drive technology, no longer meets the required safety standard or does not use state-of-the-art technology. In addition, procurement of spare parts is extremely difficult or may even be impossible.

In many cases, modernisation (retrofit) of a machine is more cost-effective than procuring a new one. In such cases, existing machines and systems can be adapted to modern standards through enhancements or conversions. Based on our many years of experience in the field of plant engineering, we can develop a solution concept that is customised to your application scenario. Request information now

We will ensure your system uses state-of-the-art technology.

How you benefit from our support:

- Increased efficiency and productivity

- Reduced downtime

- Optimised production and process times

- Increased system availability

- Lower investment costs than procurement of a new system

- Our range of services

Our range of services:

- Expansion of existing systems

- Fulfilment of current guidelines

- Identification of potential savings

- Replacement of key components

- Creation of wiring diagrams (EPLAN)

- Reduction of downtime to a minimum

- Development of solution paths and alternatives

- Secure supply of spare parts

- User-friendly operating interfaces

- Targeted training of operating personnel

Sometimes, you find the complete solution in the partial solution.

You too can benefit from our retrofit concepts.

Interested?

If you have any questions about our services or would like to receive an individual offer, feel free to contact us! Simply call us on +49-2871-21927-0 for a personal consultation. Or email us at info@meier-prozesstechnik.de.