Impregnation systems

For more than 40 years, we have constructed, manufactured and assembled systems for impregnation of electrical components in vacuum, vacuum-pressure and atmospheric processes around the world. Our systems range from small, manual systems for use in laboratories right through to fully automated impregnation systems for use in production.

Through many years of experience in these process technologies, we ensure that every customer’s desired technology is implemented in a jointly developed system concept on the basis of targeted advice. We have the expertise to develop and manufacture impregnation systems for resins and varnishes from any manufacturer.

All systems meet the European Union’s current safety provisions and include a CE declaration of conformity. Request information now

Our impregnation methods ensure long-termprotection and optimal electrical insulation for the windings of electrical motors

Meier impregnation system guarantee a reliable production process and high-quality impregnation results for your product

We develop custom system concepts so that we can offer the ideal solution for your application

System Types

System type AI (atmospheric impregnation)

Electrical components that allow the penetration of impregnation media are impregnated atmospherically. After impregnation, the subsequent curing of the resin achieves the necessary mechanical hardening of the stranded wires and components. It also achieves increased corrosion protection for the component.

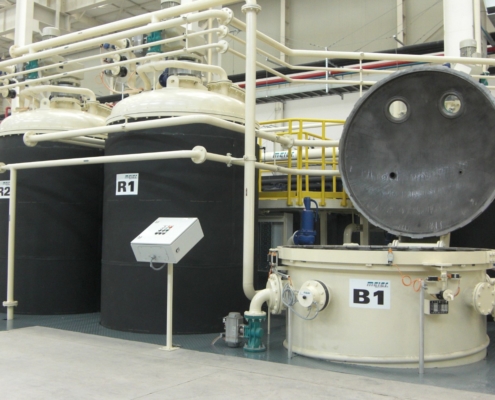

System type VI (vacuum impregnation)

Components that tend to contain air pockets due to their geometry or insulation structure are impregnated under a vacuum. The vacuum means the resin can penetrate the cavities much more effectively and moisture pockets in the component and impregnation system are avoided.

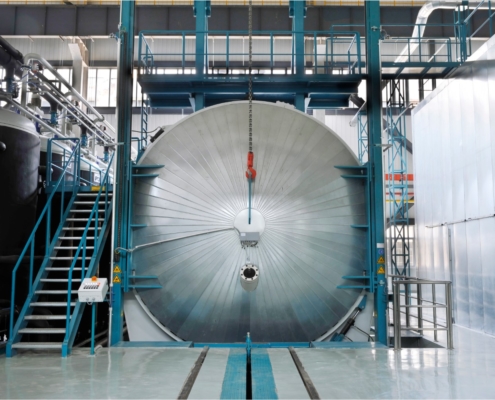

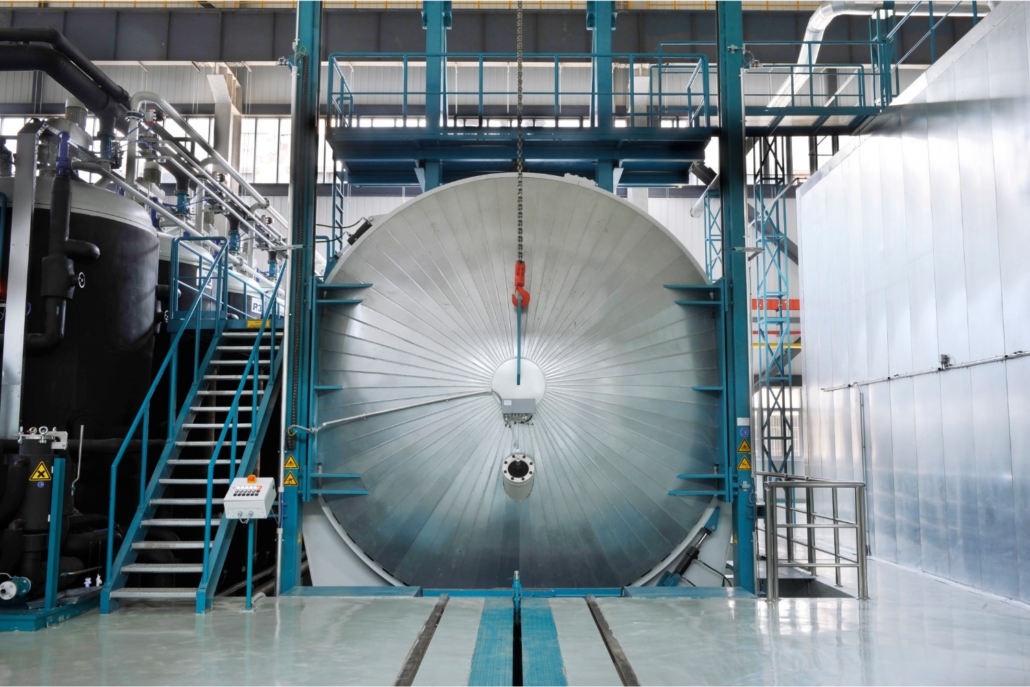

System type VPI (vacuum pressure impregnation)

In the high-voltage range, the electrical conductors are wrapped with several layers of insulating tape that must be fully soaked with the impregnation resin. For this reason, this impregnation method also involves pressurising the impregnation vessel after the vacuum, so that the remaining dead spots are completely filled, especially inside the insulation. The degree of impregnation increases with the voltage of the electrical machine.

In a vacuum or vacuum-pressure process, the spaces between the electrical steel are filled with resin, which is why this process is also attractive for the low-voltage range and transformer impregnation

We supply impregnation systems that are tailored to your precise needs in a wide range of designs and equipment:

- Vertical designs

- Horizontal designs

- Fully automated systems

- Process visualisation

- Backup, administration and evaluation of process data

Interested?

If you have any questions about our services or would like to receive an individual offer, feel free to contact us! Simply call us on +49-2871-21927-0 for a personal consultation. Or email us at info@meier-prozesstechnik.de.